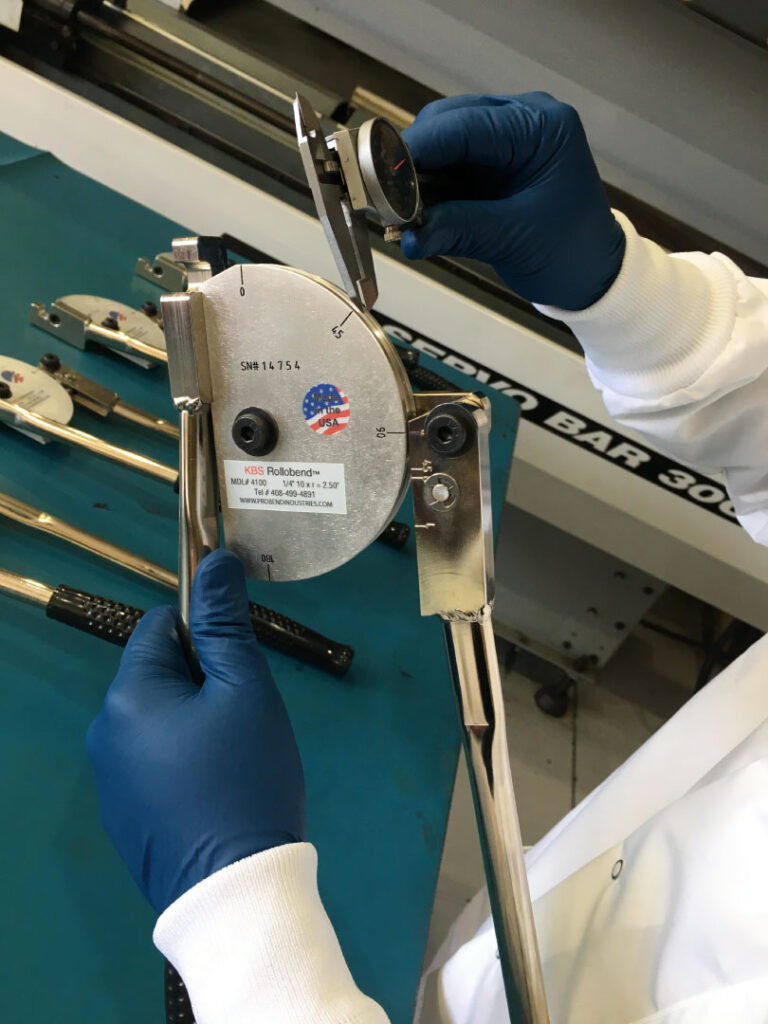

KBS Rollobend

KBS Long-Radius Roller-Bearing Tubing Benders

Get Precise and Reproducible Bends on Electro-Polished Stainless Steel Tubing. For Ultra-High Purity UHP Thin-Wall Electro-Polished Stainless Steel Tubing.

KBS Tubing Benders

Bend Steel, Stainless Steel, Aluminum, Brass, Soft and Some Hard Copper and Titanium

- Each tool bends up to 180 degrees and large radius bends are ideal for preventing smooth inside walls from cracking, flaking and generating particulate contamination.

- The open side slips over the tubing at any point. You get smooth long bends with no marking, scraping or flattening.

About Us

In the mid 1980's a well known semi-conductor fabrication facility in silicon valley was experiencing a 40% rejection rate of their chips due to particulate contamination in their process piping caused by bending tubing with standard radius tubing benders.

A contractor installing the process lines was asked if he could come up with a solution to the problem. After a couple of years of trial and error, the KBS Long-Radius Tubing Bender was invented and reduced the rejection rate from 40% to less than 10%. For a number of years now, KBS Long-Radius Tubing Benders have been required by all chip plants for contractors installing high-purity process piping.

This system has been approved and used in major micro-electronic facilities and by contractors throughout the United States.

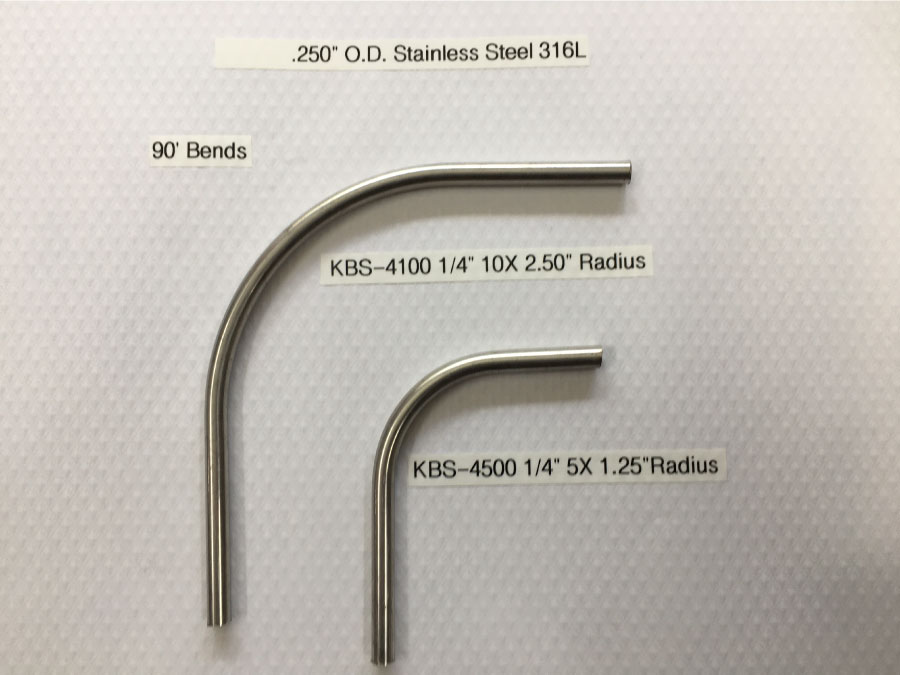

SPECIFICATIONS

For Application Assistance or to Order call (408) 499-4891

Standard Rollobend System, 2.50" radius*

| 1/4" tube OD x .035" wall thickness | 3/8" tube OD x .035" wall thickness | 1/2" tube OD x .049" wall thickness |

|---|---|---|

| Part # 4100 10X, 2.50" radius | Part # 6600 6.67X,2.50" radius | Part # 8500 5X, 2.50" radius |

Other Rollobend System Sizes, 1.25" - 5.00" radius

| 1/4" tube OD x .035" wall thickness | 3/8" tube OD x.035" wall thickness | 1/2" tube OD x.049" wall thickness |

|---|---|---|

| Part # 4500 5X, 1.25" radius | Part # 6500 5X, 1.87" radius | Part # 8100 10X, 5.00 radius |

| Part # 6100 10X, 3.75" radius |

*Recommended combination is #4100, #6600, #8500, maintaining even center-to-center distance.

These tubing benders are not for use with wall thicknesses heavier than the specification shown here, and are not designed for high-pressure hydraulic tube bending applications

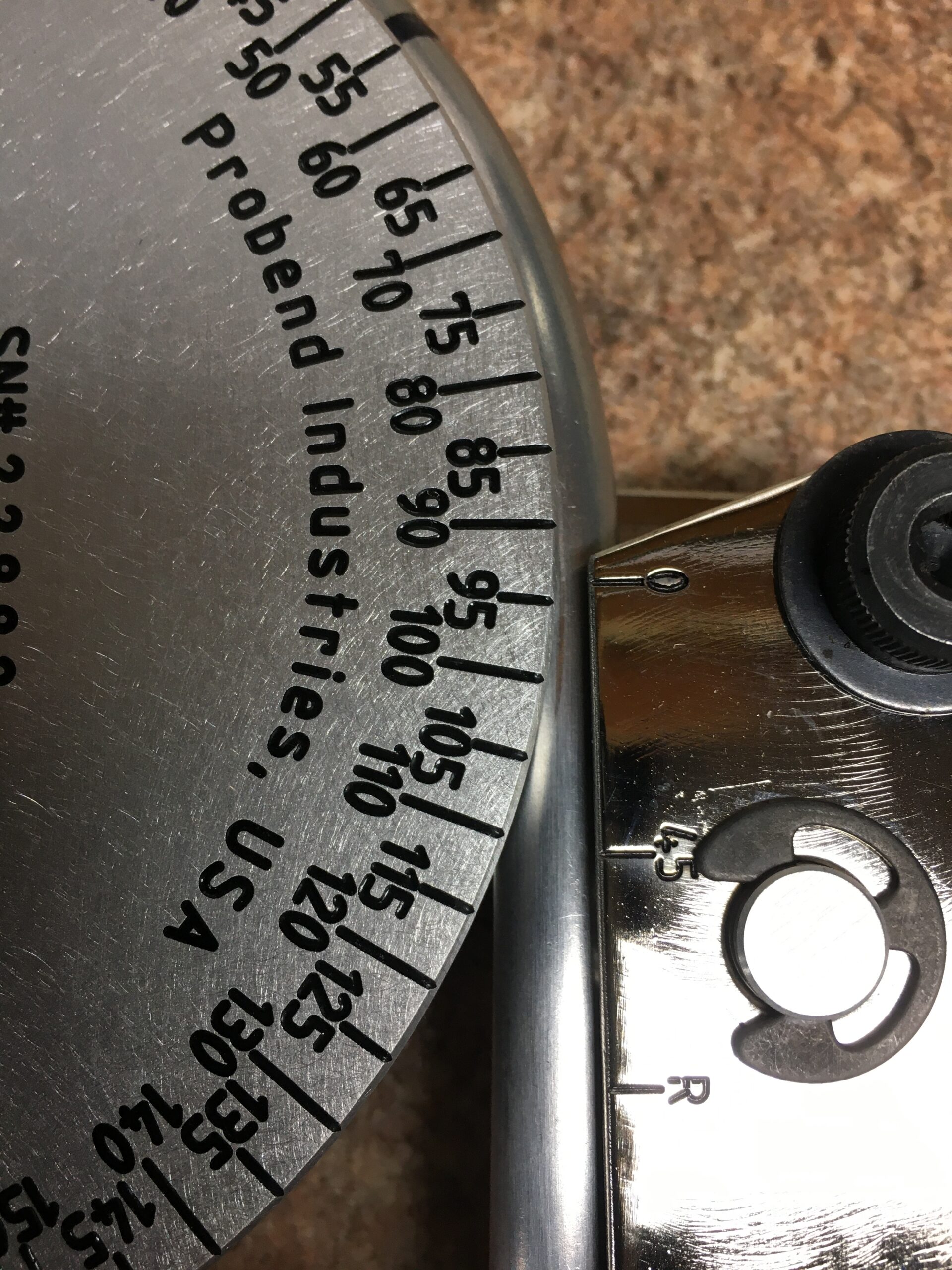

BENDER MARKINGS AND INDICATORS

Springback

With some experience you will be able to predict the amount of springback to expect. Please allow for 1 to 3 degrees of compensation.

Verify the bend angle using a template, protractor or against a known angle to ensure the correct bend angle has been achieved.

Quality Control/Quality Assurance

The rugged heavy-duty, high-quality industrial grade construction of the KBS Long Radius Tubing Benders have been providing users with consistent, precise and repeatable bends for over 30 years.